To be the one stop solution provider for all the fabrication needs across domains by 2030

To be the partner for fabricating thoughts of our customers in supporting the development of world-class products, process with assured quality, time & cost.

We are committed to manufacturing and supplying consistently high quality machined components and fabricated items to our customers on time, and we have strived to meet the needs and expectations of our customers and interested parties. We ensure compliance with applicable requirements of our customers and interested parties, as well as continuous improvement in process and products.

We lay out the plan for execution and conceptualize a required design for your product development.

We have a strong committed vendor base to aid the project-specific procurement and sourcing.

Highly skilled engineering workmanship deployed on your projects to ensure we fabricate your thoughts with assured quality.

We communicate the status to the respective stakeholder and ensure the delivery timelines are met/deployed.

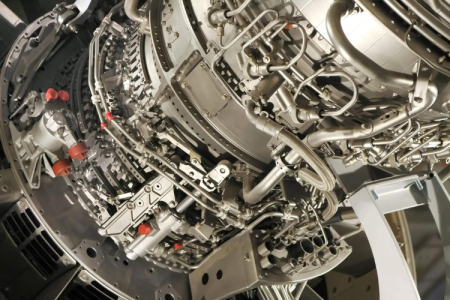

We have executed a high pressure welded pipeline for a steam turbine with 100% radiographic joints welded at the 6G position.

We have developed welded stainless steel drug processing equipment’s and containers qualifying the strict requirement of medical standards.

We have fabricated train seating and coaches, meeting the locomotive safety standards.

We have developed machined aluminum components for aerospace standards.

We have manufactured welded food-grade stainless steel food processing equipment’s and storage containers qualifying the requirement of food and safety standards.

We have developed a fixture for automotive seating assembly line component welding to enable mass production and productivity.

We develop Sheetmetal components and complex systems by fabrication.

We develop pressure vessels ranging from small to big vessels used in pharma and diary application.

We fabricate pressure pipelines and erect them on the respective systems onsite/offsite.

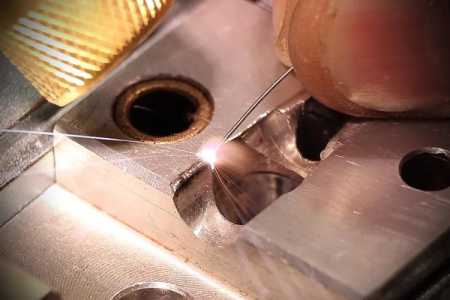

We are expertise in welding stellite the hardest material disposition to achieve resistance to erosion and corrosion.

We are expertise in refurbishing your die life by depositing the parent material in the worn-out region in the die, which hits back the die for production after machining.

We fabricate architects custom décor products and structure with high-quality style and finish.

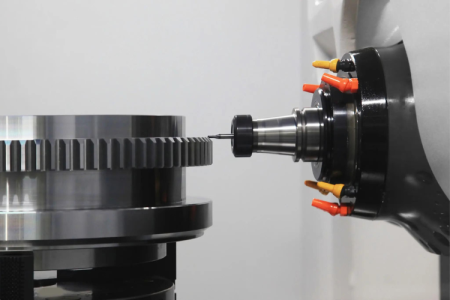

We develop precision jig and fixture for your production requirement enabling the turnaround time and consistent quality throughout your production.

We have the capability of producing machined components required for the fabrication needs of the system.

We take up reverse engineering design development and also execute new product development & solution development for your need.

Feedback from clients at DFAB.

Pragmatic culture has been in center of focus for the DFAB team to win situations amicably.

Highly experienced in the profession of welding and fabrication, with 26+ years of industrial experience executing projects in India and abroad. Niche skill in satisfying customers.

Experienced tooling engineer with 8+ years of product design background & core experience in OEM practice for product design and development, strong in process implementation and new product development.

Operating space of 7000 sqft

5 Ton Crane

10 + welding machines (TIG,MIG)

Conventional Milling & Turning machines

Radial drilling machine

Advanced Laser Technology

Skilled welder qualified for 6G positions

Experienced project engineers to facilitate product development

Quality inspector

DFAB stainless system Pvt Ltd is a start-up established on 28-Sep-2018.

Our organisation is ISO 9001 – 2015 certified and positioned in the prime location of Peenya industrial area, we offer end to end solution in the field of equipment fabrication & machining, with 7000 sq-ft operating built-up area and we are equipped with a highly skilled team with domain experience to craft the service to your products, we have significant in-house talent to provide services like pressure vessels fabrication, high-pressure pipeline welding, heavy engineering and component machining.

Are mainly into Machining components for

Automotive, Earth moving Equipments and Heavy Machinery sectors

© 2023 -24 Dfab Stainless System Pvt. Ltd. Designed and Developed by: Wealth International